Sources of Ferrous Scrap and Non-Ferrous Scrap

Autos are one of the significant sources of ferrous scrap for the secondary metals market. Automobile lifespans have increased in recent years, thanks to the development of precision and anti-corrosion treatments on metals and the increased longevity of power trains. Approximately 60% of all deregistered cars are processed through scrap shredders and sold to iron and steel mills. The auto dismantling industry also stores left-over autos to inventory used parts.

Mixed iron is the most common grade of ferrous scrap.

Ferrous metals are steel and iron that contain iron. These metals are magnetic and are used to make a variety of alloys, including stainless steel, tool steel, and carbon steel. The primary source of ferrous metals is scrapped vehicles. Non-ferrous metals don't contain iron but have mechanical properties similar to steel and iron. For example, aluminum, titanium, and other non-ferrous metals are used in similar applications as steel and iron.

ferrous scrap can be sorted according to its composition and size. Mixed iron is the most common grade of waste, consisting of integrated iron and steel. It is separated into two types: unprepared and prepared. An impromptu plate is any metal that is larger than these sizes. Both types of ferrous scrap must be free of contamination and be a minimum of four feet by two feet. For further information about ferrous scrap classification, check the specifications on your local yard's website.

The price of ferrous metal fluctuates each month, reflecting global supply and demand. However, it ultimately ties back to steel prices. When prices drop, it affects both domestic and export markets. While domestic scrap prices are relatively stable, they can fluctuate dramatically with the overall demand. In addition, the availability of iron resources in the United States may lead to price fluctuations. In general, mixed iron scrap is more valuable than non-ferrous metal.

Busheling scrap is clean steel scrap.

Busheling is a prime grade of industrial scrap, defined as a clean, unused piece of metal not exceeding twelve inches in any dimension. Busheling can be wrought iron or soft steel pipe material that has undergone a manufacturing process and is free of coatings or rust. Busheling can be either new or used but is generally the highest-recovery scrap. Depending on the manufacturer, busheling can be fabricated into a bundle according to the size and weight specifications required by the consumer.

The market for this metal type is relatively stable, with prices remaining in the mid-to-high range. Prices for prime scrap, including busheling, were modestly higher than rumors suggested, although the increase fell short of the expected $40-to-60 per-ton range. Sellers felt confident that the domestic market would follow the export market's signals, and it did. Busheling scrap traded for $270 to $280 per ton in the Midwest, and a few primary buyers bought up to 300,000 tons for delivery in May.

Metal production factories, which generate large volumes of busheling scrap, often process it and sell it in bulk. Many maintain tie-ups with scrap collectors and offer yard transportation and on-site pickup. Scrap Monster, an advanced trading platform, provides a marketplace for all types of scrap. The marketplace also has a database of scrap yards so that you can easily find one that accepts your chip.

Machine shop turnings and iron borings are non-ferrous metals in a 'free state.'

In their 'free state,' non-ferrous metals are in their simplest form, without oxidation or impurities. These are the most common types of non-ferrous scrap and include iron and steel turnings, rail chips, and other materials that cannot be recycled. Additionally, they must be at least 75 pounds/cubic foot in their original production state.

These scraps are typically 'clean' cast or malleable iron. Iron borings must be free of scale, lumps, or excessive oil. They may also be 'cut to size to meet specific specifications. Steel turnings are also non-ferrous metals in a 'free state'; they must be free of rust or paint. Other non-ferrous metals are 'free' if they are not allowed. These are typically found in machine shops and are purchased in solid or turning form. The remaining percentage of metal is called 'breakage metal.' The percentage of copper in non-ferrous metals is based on the recovery rate of the copper in the scrap.

Steelmaking slag scrap is a low-grade melting material.

Steelmaking slag is a valuable secondary resource because of its significant metal content. The French steel industry, for example, generated large volumes of this material. Its morphology and mineralogy are essential to its chemical and volumetric stability, and they may be influenced by the process used to create it. This literature review aims to provide an overview of the generation of this material.

Steelmaking slag is a by-product of the steelmaking process. It is produced during the separation of molten steel from impurities in the blast furnace. It is a mixture of oxides and silicates that solidifies upon cooling. Integrated steel plants generally use the basic oxygen process, while specialty steel plants use the electric arc furnace process. In addition to slag, steelmaking operations also generate low-grade scrap from this material, valuable to recyclers. In addition to its high-quality properties, steelmaking slag scrap has low carbon content. The carbon level in the steelmaking slag is approximately 0.25 percent higher than the final tap level. Basic slag contains 55 percent lime, 15 percent silica, and roughly twenty percent iron oxide. Often, carbon is added to the slag to make it foam. Carbon monoxide gas reacts with the iron oxide in the slag and allows for higher power settings. Oxygen blowing or carbon injection may reduce the carbon level of the steel but increases the carbon content.

Steelmaking slag is exported to mills in other countries.

Approximately half of all steel production is exported to other countries, with less than a third of this slag recycled. In nations such as China and Japan, only a small percentage is recycled. In China, however, the slag from steelmaking plants is exported to mills in other countries and recycled into new steel. The slags exported to other countries are used to create new steel but are also an important source of pollution for the surrounding environment.

Globally, over 600 million tons of steelmaking slags are produced each year, with about half of that amount going to steelworks. Steelmaking slag is exported to mills in many countries, as well as to other countries. LD slag is the most widely used slag, while steelworks slag is shipped to mills in other countries. The slag is also used as a filler in the construction industry. Slag production has been increasing worldwide, with an estimated 25 million tons of slag traded globally, with 12 million tons exported to other countries. In addition, 50 to 60 million tons of slag are transported within countries, with many mills relying on water transport to move the slag. While water transport is a relatively inexpensive method, new grinding and blending plants are being constructed near blast furnace systems worldwide.

Copper is the most valuable non-ferrous metal.

When it comes to non-ferrous scrap, copper is king. This metal is a combination of iron and carbon used for construction and automobiles. Compared to other metals, steel weighs more. Steel accounts for about half of all ferrous scrap supplies. In addition to its high value, copper is also widely used for various consumer goods, including jewelry, home appliances, and construction materials.

When deciding how to recycle ferrous scrap, it is essential to consider the price of the various metals. Metals like steel and iron are more valuable than copper. Iron is widely used in construction and is common in most products. On the other hand, Brass is standard as non-ferrous metal, though it is yellow with a red tint. Brass combines copper and zinc, and its dense nature increases its value.

Although ferrous metals are easy to recycle, non-ferrous metals are worth more at a scrapyard. Copper is the most valuable non-ferrous metal for ferrous scrap, gold, silver, and bronze. Copper is also one of the oldest metals to be forged and was the first metal used to make tools. After that, it was followed by bronze and iron, which marked the beginning of the production of ferrous metals.

Cleaning and de-pollution of ferrous scrap

ferrous scrap is a collection of steel, iron, and stainless steel products from manufacturing and end-of-life processes. Because of their value as metals, ferrous scrap is often processed or remelted into new products. Recycling of ferrous scrap began long before environmental concerns were shared. But, these concerns have shifted the way the industry treats this waste. Here's what you can expect from a de-pollution process for ferrous scrap. In addition to de-pollution, cleaning and sizing ferrous scrap involves removing hazardous materials that could cause an accident. These include asbestos and radioactivity. The former is particularly dangerous for workers, as they can contaminate materials intended for metal smelters. Scrapyards typically contain specialized tools that can pose a safety risk. A number one busheling scrap includes a large volume of steel clippings up to 300 mm. It excludes old auto body, fender stock, coated metal, and 0.5 silicon.

The recycling of ferrous scrap begins with the recycling of passenger cars. While consumers use a small percentage of this material, the scrap recycling industry processes the vast majority. Most scrapyards use several processes to sort and prepare ferrous scrap for commodity-grade specifications. A shredding process developed in the late 1950s allows the processing of large items and non-ferrous material.

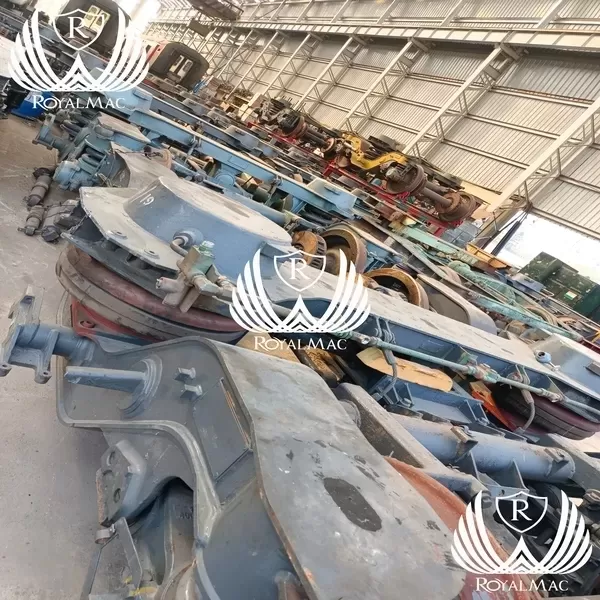

CUSTOMER DOUBTS ABOUT ROYALMAC RAIL SUPPLY IN GLOBALLY

One of the vital pieces of information for our customers from all over the world who have doubt about rail line importing when they order Rail line or HMS to RoyalMac for recycling it to their countries.

Many traders do not know is that scrap steel is prohibited to be exported or Importing from various countries by government decision. We, in RoyalMac, provide solution to our Costumers the product of unsuitable rails to be good tracks for trains and did not pass the tests of conformity of measurements due to the different sizes and inequalities and it carries HS CODE: HS73021000. They are thus not suitable for installation as a trainSo we cut it into multiple sizes But it is not classified as scrap: 1,00m | 1,20m | 1,50m | 1,80m | 2,00m | To be ready for recycling at a lower cost.

“ We always strive to provide solutions for our valuable customers “